Walnut blasting to protect against carbon deposits in the inlet ducts

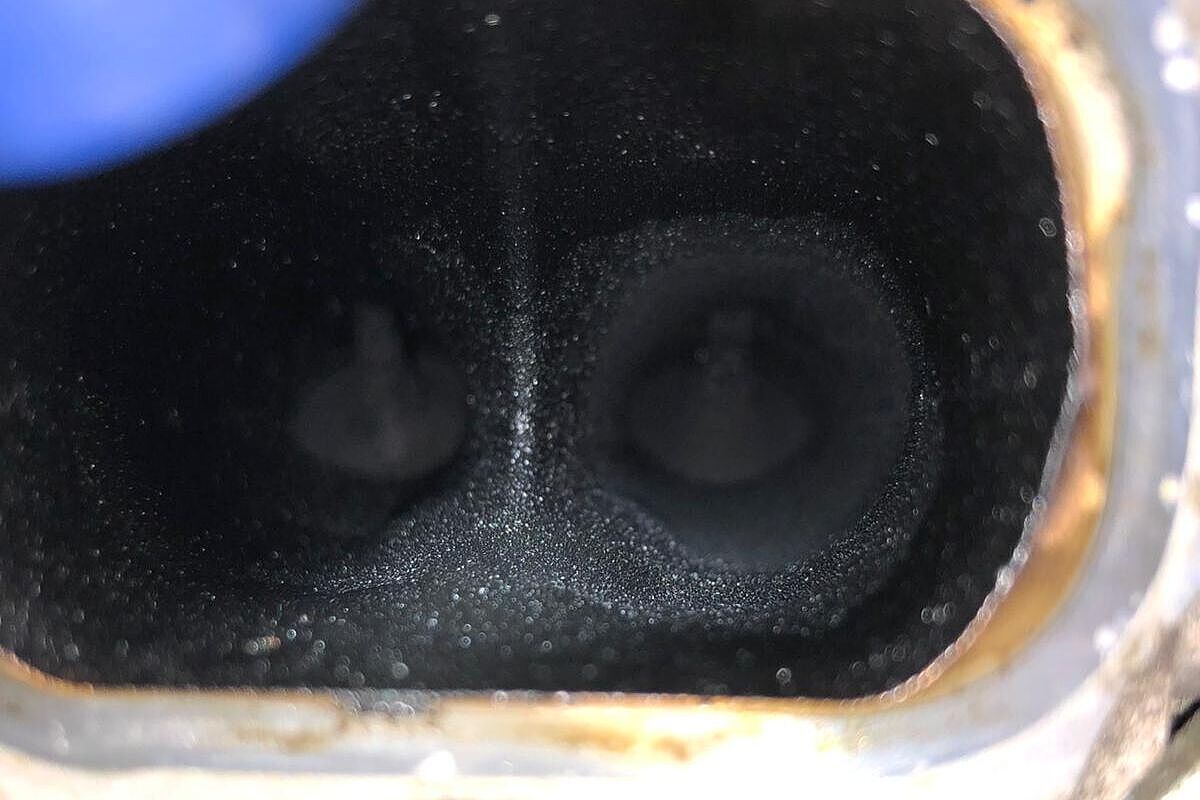

Carbon deposits in the intake ducts, especially on the valves, disrupt the flow of combustion air in the intake stroke and prevent the valves from sealing the combustion chamber. This results in engine malfunctions, which are noticeable in the form of intermittent running at idle or when driving.

The fault pattern affects all gasoline engines with direct injection, but is far less pronounced in engines with additional intake manifold injection or injection - such as natural gas engines.

- This is caused by the engine concept

Oil-containing vapors from the crankcase are fed into the intake manifold behind the throttle valve. However, many oil particles do not enter the cylinder with the fresh air, but stick to the walls of the intake ducts and valves.Direct injection eliminates the "scavenging effect" in the intake port, as the fuel is only fed to the combustion air in the cylinder. High exhaust gas recirculation rates cause the temperature in the intake port to rise. While the liquid components of the accumulated engine oil evaporate, the solid components dry out. The result is the formation of oil carbon, which constantly increases over the running time.

- In addition to jerking of the engine, the formation of oil carbon leads to a gradual loss of performance

- Walnut blasting is a useful preventive measure for trouble-free operation

- Previously, the cylinder head had to be dismantled and the inlet valves removed to remove the oil carbon

- All components then had to be cleaned manually and the valves then reground

- Cleaning with our cleaning device is easier and considerably less time-consuming

- It also removes stubborn carbon deposits using compressed air and a special cleaning granulate made from walnut shells

Procedure:

- First remove the suction pipe so that the inlet ducts are accessible

- The fine walnut shell granulate is then blown into the inlet channel and onto the valves using compressed air at a pressure of 6 - 8 bar. The valves are closed during this process

The granulate contaminated with the dissolved coking is extracted by a vacuum cleaner via an adapter during the blowing process

The fine granules of the granulate remove the coking almost completely, but at the same time are so soft that they do not attack the inlet duct or the valves themselves

Residual components of the granulate are burnt off in the cylinder and therefore have no negative effect

Our range of services for your Volkswagen, Audi, Seat or Skoda:

4-cylinder gasoline engines (1.0l-1.6l): Complete price: from 450,- €

4-cylinder gasoline engines (1.8l-2.0l): Complete price: from € 499

6-cylinder gasoline engines (3.0l-3.6l): Complete price: from € 809

* all figures incl. labor, granulate, small parts & gaskets!

* other engine types such as 8-cylinder etc. on request